Types of Fibers Used in PrePreg Composite Materials

Glass Fiber

Glass fibers are widely used in composite materials. Glass fibers are amorphous polymers, reinforcement materials with high chemical resistance, long life, high electrical insulation, high density, flexibility, lightness, workability, high tensile strength, low heat transfer coefficient and low cost.

Glass fibers are produced with the desired properties according to the materials used in their production. In order to produce high quality fibers, high purity materials must be melted homogeneously, drawn at high temperatures and then a protective coating must be applied. Glass fiber types;

• A (Alkali) Glass: It is the most commonly used glass type. Since it contains high levels of alkali, it has poor electrical insulation properties. It has high chemical resistance. It is used in window glass and bottle production. It is rarely used in composite materials.

• C (Corrosion) Glass: Shows high chemical resistance. Used in the production of storage tanks.

• E (Electrical) Glass: Due to its low alkaline properties, its electrical insulation is much better than other glass types. It is the most common type of glass fiber used as a reinforcement component in polymer matrix composite materials. The reason for using E-glass fibers in composite materials is due to their high tensile strength, heat, fire, chemical and moisture resistance properties. E-glass is known as economical glass.

• S (Strength) Glass: It has a tensile strength value that is 33% higher than E glass. In addition to being a high strength glass, it is also highly resistant to fatigue at high temperatures. Due to these features, it is used in industries that require high mechanical properties and thermal resistance, such as space and aviation. S-glass fiber diameters are small (half of E glass), so the number of fibers is high. Since the number of fibers is high, it has a higher bonding feature.

Carbon Fiber

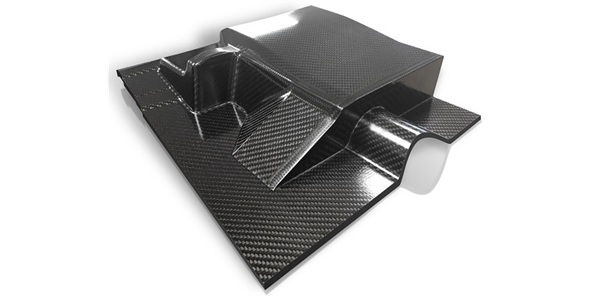

Carbon is a nonmetal that forms the main element of coal and organic compounds. The density value of carbon fiber varies between 1.6-2.2 g/cm3 depending on the type of raw material used in carbon fiber production and the processing temperature. Carbon fibers have positive properties such as low density, high strength, toughness, high hardness, high fatigue resistance and negative thermal expansion coefficient, but also negative properties such as high cost, low impact resistance and high electrical conductivity. Its low density has made it possible to produce lightweight and high strength materials. For this reason, it is used in sectors where cost can be ignored such as space, aviation, automotive, medical and marine.

Aramid Fiber

Aramid fiber is made up of aromatic polyamide chemical. Aramid fiber has advantageous properties such as low density, high tensile strength, high abrasion resistance, high chemical resistance, high tensile strength and high impact resistance. The compressive strength of aramid fiber is 20% of the tensile strength. For this reason, it is not recommended for use in structural applications that include high compressive loads in aramid-reinforced composite structures. Some aramid fiber types degrade when exposed to sunlight for a long time. Due to this feature, the place of use of aramid fiber is very important. The appropriate material should be selected for the area of use. Aramid fiber is used in ballistic, protective clothing, marine, aircraft, automotive, electromagnetic cables and friction linings in clutches.

|