|

|

|

|

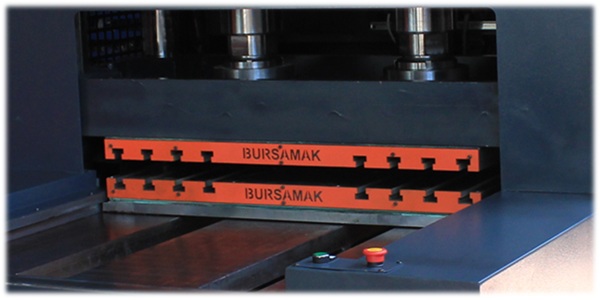

Standard Vulcanization Press |

ECO Vulcanization Press |

Laboratory Vulcanization Press |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

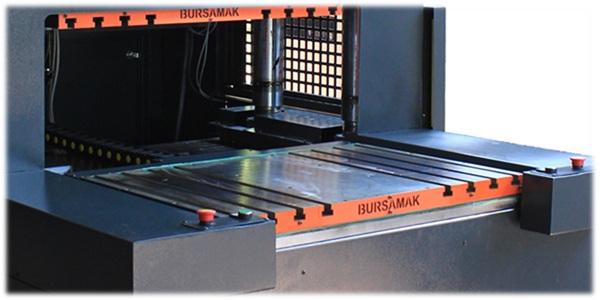

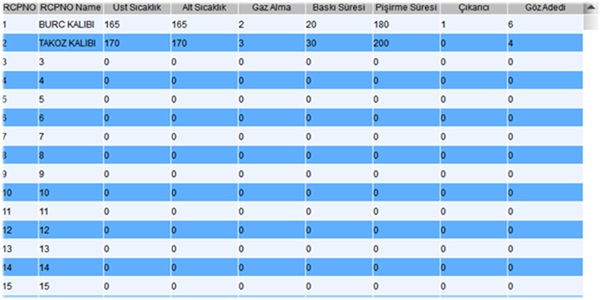

Vulcanization Press Models

|

|

|

|

| MODEL | Standard Vulcanization Press | ECO Vulcanization Press | Laboratory Vulcanization Press |

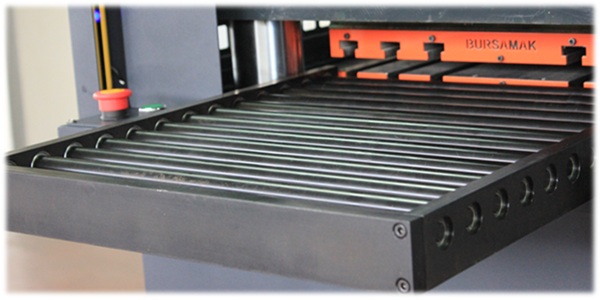

| Hydraulic Sliding Table | Standard | --- | --- |

| Middle and Side Extractor Mechanism | Option | Option | --- |

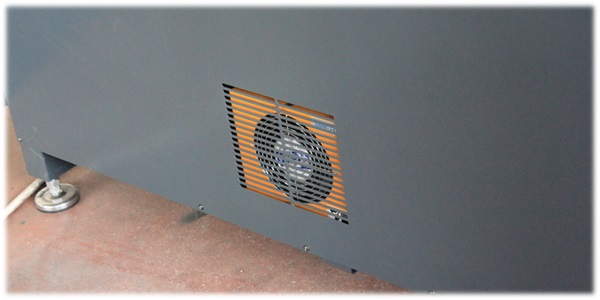

| Hydraulic Oil Cooling Unit | Standard | Standard | --- |

| Ventilation | Standard | Standard | Standard |

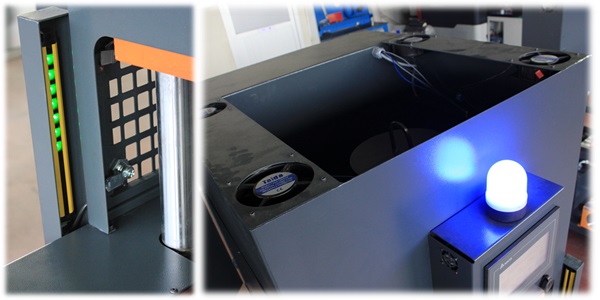

| Safety Light Barrier | Standard | Standard | --- |

| Automatic Degassing | Standard | Standard | Standard |

| Automatic Operation and Shutdown | Standard | Standard | --- |

| Electronic Pressure Monitoring | Standard | Standard | Standard |

| Automatic Lubrication | Option | Option | --- |

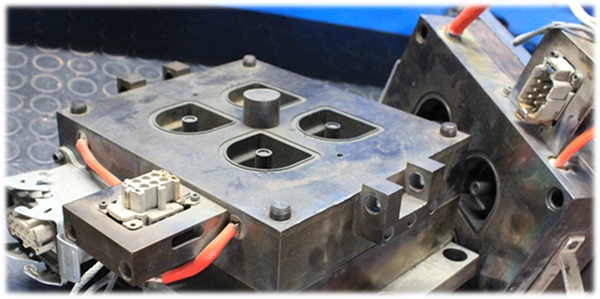

| Mold Parameters Memory | Standard | Standard | --- |

| Operator Delay Warning | Standard | Standard | --- |

| Heating Technology | Standard | Standard | Standard |

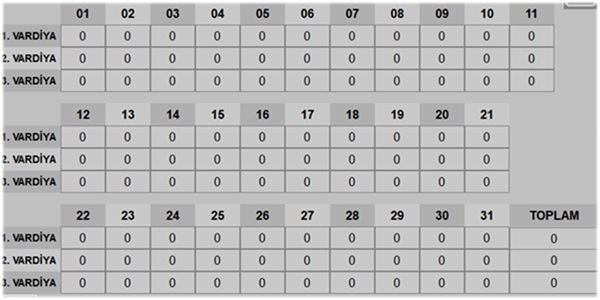

| Shift Production Tracking | Option | Option | --- |

| Direct Mold Heating | Option | Option | --- |

| Server Connection and Remote Control | Option | Option | --- |

| Temperature Statistics of Tables | Standard | Standard | --- |

| Energy Consumption Tracking | Option | Option | --- |

| Multilingual Control Panel | Standard | Standard | --- |

Standard Vulcanization Press |

ECO Vulcanization Press |

Laboratory Vulcanization Press |

|

BROCHURE |

BROCHURE |

BROCHURE |

Yaylacık mh. 44. sk. No:13 16280 Nilüfer / BURSA /TURKEY

+90 224 3611940-41 info@bursamak.com