|

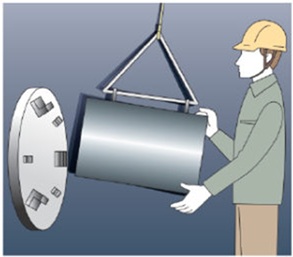

Loading parts onto a vertical grinding machine

In vertical grinding machines, loading is much easier. The increase in weight and the increase in the diameter of the part do not cause any negative effects. Thanks to gravity, there is no parallelism problem.

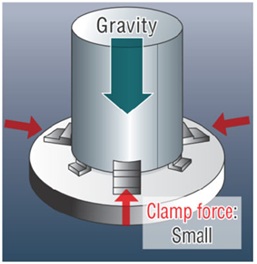

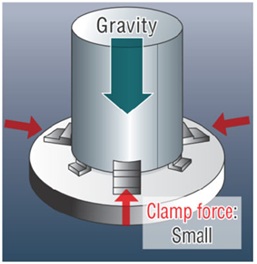

Clamping workpiece on vertical grinding machine

Since the load is always equal, it provides much higher circularity accuracy. Since the load is equal and very low to each connection point, the need for maintenance is much lower.

For parts that need perfect concentricity, such as parts that are heavy and may interfere with horizontal machining strategies, vertically oriented profile grinders offer the stability and precision required.

Main Features of Vertical Grinding Machine

Gravity-Assisted Stability: Vertical installation allows the workpiece to lean naturally against the chuck, minimizing vibration and supporting heavy parts.

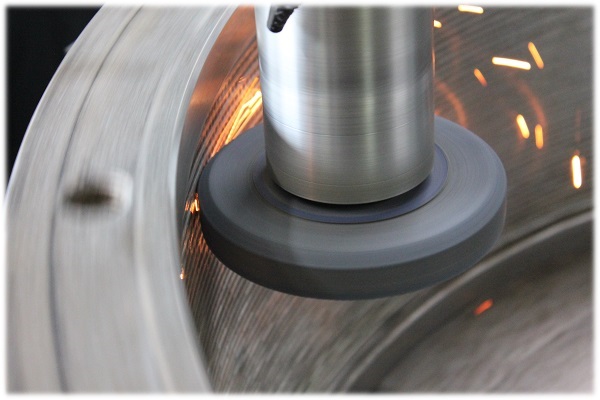

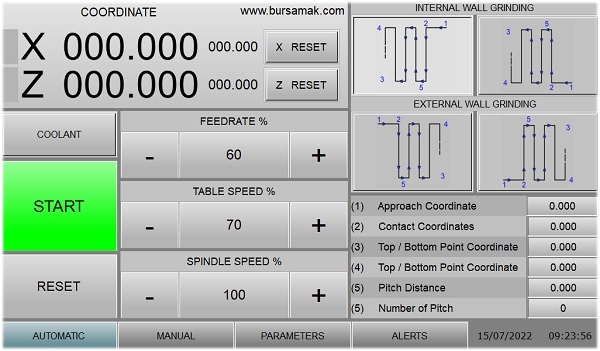

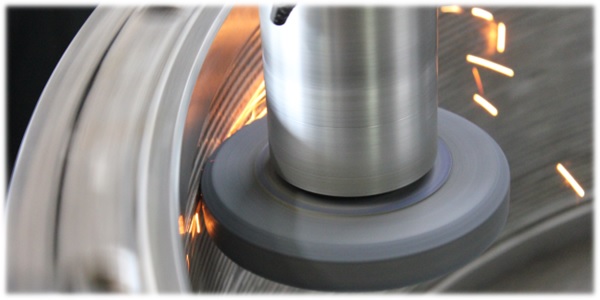

Multi-Process Capability: Reduce errors and increase productivity by performing Internal Grinding (ID) and External Grinding (OD) operations in a single setup.

Area Efficiency: Vertical grinders require less floor space while maintaining full machining capacity.

The CNC Vertical Grinding Machine is a must-have for manufacturers who need high-precision machining of large, round and heavy workpieces. Its multi-processing capability, compact design and automation-ready features make it ideal for both high-volume and special jobs.

|