|

|

|

|

|

ЭКО Вулканизационный пресс

| МОДЕЛЬ | RP403 | RP406 | RP410 | RP610 | RP615 | RP620 | RP915 | RP920 | RP925 |

| Размеры стола (мм) | 400 X 400 | 600 X 500 | 900 X 600 | ||||||

| Сила прессования (250 бар) тонн | 40 | 80 | 125 | 125 | 200 | 250 | 200 | 250 | 300 |

| Сила прессования (200 бар) тонн | 30 | 60 | 100 | 100 | 150 | 200 | 150 | 200 | 250 |

| Мощность двигателя (кВт) | 3 | 5,5 | 7,5 | 7,5 | 11 | 15 | 11 | 15 | 18,5 |

| Мощность нагрева стола (кВт) | 15 | 15 | 15 | 25 | 25 | 25 | 35 | 35 | 35 |

| Количество цилиндров | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 3 |

| Диаметр цилиндра | 150 | 200 | 250 | 250 | 230 | 250 | 230 | 250 | 230 |

| Гладить | 250 mm | 300 mm | 350 mm | ||||||

| Максимальный зазор | 270 mm. | 320 mm. | 370 mm. | ||||||

| Минимальный зазор | 20 mm. | 20 mm. | 20 mm. | ||||||

| Скорость нажатия | 10 мм/сек. | ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| МОДЕЛЬ | Стандартная вулканизация пресс | ЭКО вулканизация пресс |

| Гидравлический подвижный нижний стол | Стандартный | --- |

| Механизм среднего и бокового экстрактора | Вариант | Вариант |

| Блок охлаждения гидравлического масла | Стандартный | Стандартный |

| Вентиляция | Стандартный | Стандартный |

| Световой барьер безопасности | Стандартный | Стандартный |

| Автоматическая дегазация | Стандартный | Стандартный |

| Автоматическая работа и выключение | Стандартный | Стандартный |

| Электронный контроль давления | Стандартный | Стандартный |

| Автоматическая смазка | Вариант | Вариант |

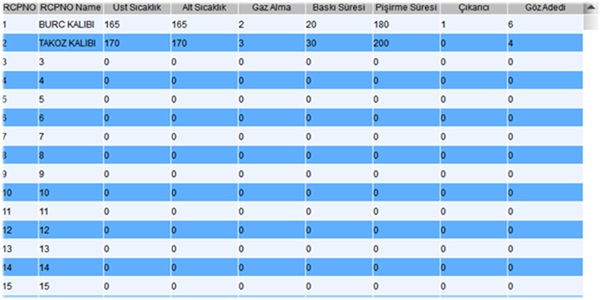

| Память параметров пресс-формы | Стандартный | Стандартный |

| Предупреждение о задержке оператора | Стандартный | Стандартный |

| Отопительная техника | Стандартный | Стандартный |

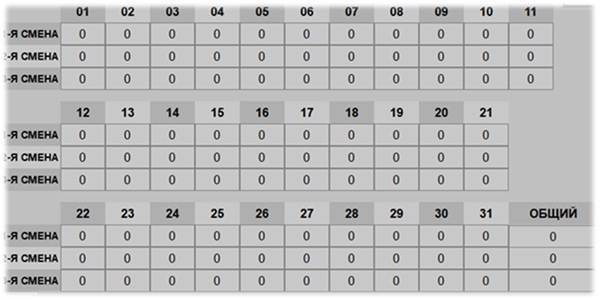

| Отслеживание сменного производства | Вариант | Вариант |

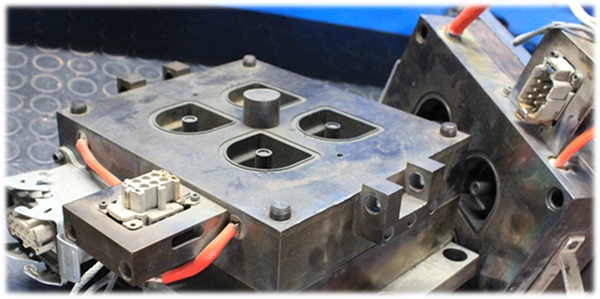

| Прямой нагрев пресс-формы | Вариант | Вариант |

| Подключение к серверу и удаленное управление | Вариант | Вариант |

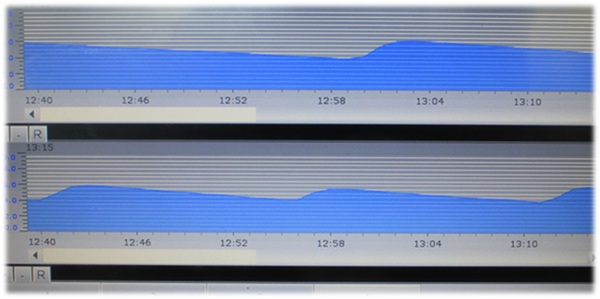

| Статистика температур таблиц | Стандартный | Стандартный |

| Отслеживание потребления энергии | Вариант | Вариант |

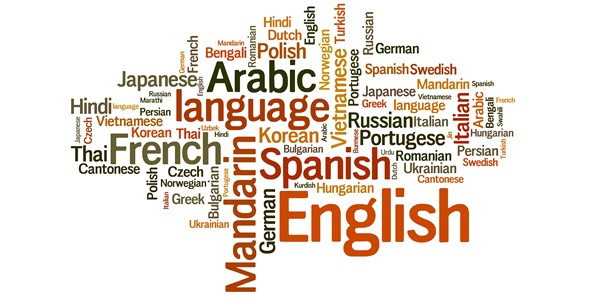

| Многоязычная панель управления | Стандартный | Стандартный |

Стандартный вулканизационный пресс |

ЭКО Вулканизационный пресс |

Лабораторный вулканизационный пресс |

|

БРОШЮРА |

БРОШЮРА |

БРОШЮРА |

Yaylacık mh. 44. sk. No:13 16280 Nilüfer / BURSA /TURKEY

+90 224 3611940-41 info@bursamak.com